Before

After

If it looks like a car crash, well it was!

The Definitive Guide to Battery/System Garage Refurbishment

Dear Viewer / Reader

The first section of this website / booklet shows examples of over 20 Battery or System Garage types and their before and after states.

From page 7 important issues such as asbestos, liability, security, water drainage, repair costs, condensation, maintenance and new construction approaches are dealt with in detail.

After page 20 there is a model by model index of the types that we have dealt with and our suggestions of the options available. This web based information is also available as a 40 page booklet free of charge. Just call 01386 430 121 for your copy

More before and after examples follow

Page 1

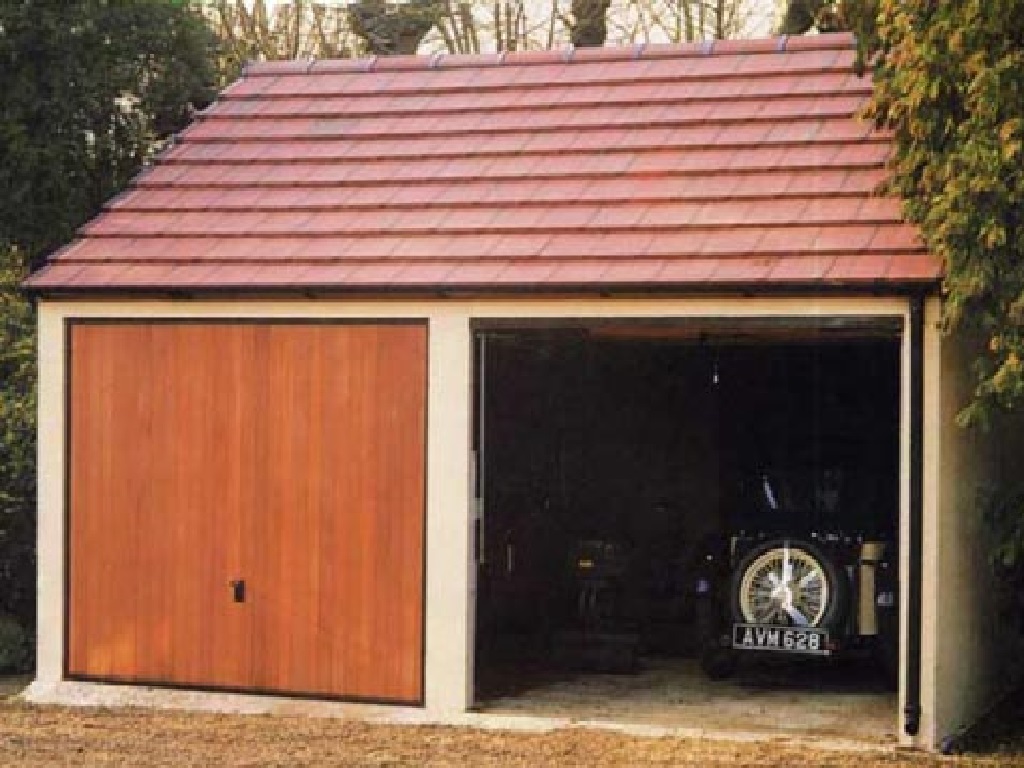

Some Completed Projects – Single / Twin Units

Page 2

Some Completed Projects – Multiple Units

Page 3

More Before & After

Page 4

Now for a more challenging refurbishment

This block of System B Garages was partly demolished by a large tree falling in the middle of the first four garages from the left hand end. While we have several moulds for the lintels and posts, of this type, we have but small numbers of moulds for the three types of panels used in this design. Without a quantity of the these moulds it would have taken weeks/months to make enough concrete panels to complete the job. Therefore we used standard Marley-Designed panels for the sides, rear and interwalls of the reconstruction.

Page 5

Another way to refurbish garages – but not our way!

Page 6

And now for the Specifics

All about the Concrete

Block Refurbishment

Page 7

More problems with the concrete. With some Marley models there is a problem with the upstand at the top of the post/downpipe. This extension “blade” at the top of the post breaks off and falls. I weighs about 20lbs. This could injure anyone standing below it.

With System B and several other now obsolete types there are other problems.

An additional problem here is the post width used by Marley (and others using the same concept) to accomodate their rainwater downpipe. This measures 235mm in width and frames the door. This concrete post not only reduces the Wing Mirror Clearance (WMC) but splits or spalls zing shown. This is a result of water freezing in the blocked downpipes.

Wih a roller shutter door the post/downpipe is the same thickness as the garage dividing wall only the roller shutter door guides protrude into the WMC thus increasing the WMC to 2294mm. Therefore the extra WMC obtained over the original Marley door is 2294-2179=115mm (nearly 5 inches) and over a Hormann door 2294-2024=270mm (over 10 inches).

With all types – Purlin failure.

Inside the garage there are more hazards, in particular cracking purlins that support the roof. They start as hairline cracks, often resembling cobwebs. It they don’t then they need to be replaced, and soon.

Page 8

With System B the problem is much the same.

Page 9

Page 10

Page 11

With our roller shutter door there is no mechanism. The spring and other parts are contained within the roll of slats. And, as an added benefit, there are no levers and springs exposed which could be a safety hazard. Plus all of the interior space is available for storage and shelving.

Page 12

Page 13

More about Safety, Liability and Security

So the ideal System or Battery Garage would have non-corroding lintels, non-corroding downpipe posts to carry the rainwater away, a component to stop under panel water ingression and inexpensive, current guttering to add a modern look at very low cost. Our new System LX meets all of these criteria.

Page 14

Page 15

Note the aluminium joining post in the centre of the rear wall. In this garage this post has increased the width by 76mm (3″) which means 3″ of extra wing mirror clearance when driving in. Also on the outside of the building the post has sockets to support solar panel arrays or lighting or security camers, even flower baskets! These posts can be inserted into the walls at any point giving a multitude of options.

Page 16

All about Maintenance Problems

The fascia gutter cover on the right (not ours) needs to be removed for gutter cleaning. This envolves removing and replacing 30-40 self tapping screws, which after a few removals will have opened up their hole so that they no longer hold and larger screws will be needed. With our gutters you just blow or brush them out. See the roof view on page 10.

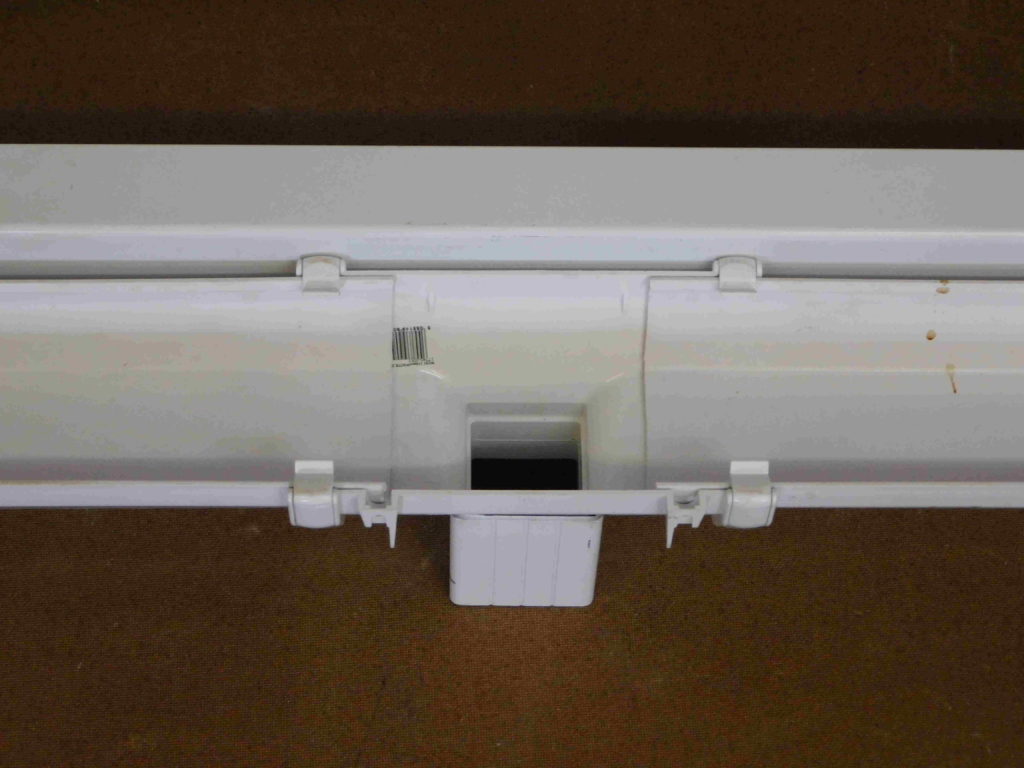

Yes, this is the front of the garage. In our System 8FX we use accessible square flow uPVC guttering that is easily cleaned by anyone with a short ladder and no tools.

All about Collision Damage

Page 17

Page 18

System LX Battery Garage Detail

The front post which doubles up as the down post with 2.8 times the capacity of the current pipes that are encased in concrete. Virtually no chance of a blockage.

The roller shutter door guides slide into the front post. This gives an integrated lintel support section equal to an “I” Beam measuring 200mm by 150mm and 5mm thick. Which is massive.

The “Z” shaped alumnium lintel which supports the roof sheets is fixed to the post/guides combo.

Page 19

The aluminium downpipe/post will not block easily, unlike the interpost pipes of earlier models. In fact the new post/pipe has about three times the capacity of the original Marley design or the System “B” Type .Debris drops out of the pipe and is easily brushed away.

Page 20

Page 21

System B

Very popular design. Often seen in the Midlands and the South. Manufacturer went out of business probably 50 years ago. All parts have been re-moulded by Leofric and are available. Can be converted to System X fronts and Roller Shutter Doors. For more information see Page 27.

Page 22

System C

Similar to Marley and Leofric Models in that they feature 16″ wide wall panels that are 7′ high. Not tongued and grooved like Marley. Manufacturer went out of business about 10 years ago. Can be converted to System X fronts and Roller Shutter Doors. Few examples around.

System E

Unknown manufacturer. Posts are embedded in the base. Walls are Post and panel construction. No parts available. Best demolished. No Further information.

System K-8F

This is a Post and Panel Garage System with concrete fascia/gutter/lintels and downpipes. No parts available but easily converts to System X fronts.

System L

Early Leofric Model – all parts available. Can be converted to System X fronts and Roller Shutter Doors. For more information see Page 28.

System M-8G

Early Leofric Model – all parts available. Can be converted to System X fronts and Roller Shutter Doors. For more information see Page 29.

System M8/9R

Very early Marley Garage – extra wide rear-sloping design using Marley A63 panels. Can be converted to System X fronts and Roller Shutter Doors.

Page 23

System M-H

This garage style used Marley’s Top-of-the-line Heritage Range in a

Battery format. All parts are available. For more information see Page 30.

System M-Q

Another early Marley design. Can be converted to System X fronts and Roller Shutter Doors. For more information see Page 31.

System M-E8/9 F/R

Marley Economy Range. Available with 8′ or 9′ interior widths. All parts available. Can be converted to System X fronts and Roller Shutter Doors. For more information see Page 30.

System M8/9F

Current Marley design. All parts available and can be converted to System X fronts and Roller Shutter Doors. For more information see Page 32.

System M8/9R

Current Marley design. All parts available and can be converted to System X fronts and Roller Shutter Doors.

Page 24

System FMTF

Unknown manufacturer. Probably best demolished. For more information see Page 32.

System TAR

Manufacturer long gone. If significant quantities of parts are required then moulds can be made. For more information see Page 35.

System TPP

Probably Cotswold. Long gone, no parts available. Walls are large Four foot square panels. No parts available. For more information see Page 36.

Page 25

System V

Probably Cotswold. Long gone, no parts available. Walls are large Four foot square panels. No parts available. For more information see Page 36.

System WMR

Obsolete design. No parts available. For more information see Page 37.

System WPF

Obsolete design. No parts available. For more information see Page 37.

System WNR

Obsolete design. No parts available. For more information see Page 38.

System YPP

Obsolete design. No parts available. For more information see Page 38.

Page 26

System B Battery Garage Detail

System B battery garage form the garage stock of many local authorities and as the original mnufacturer went out of business 30-40 years ago we have manufactured moulds for all 12 concrete components.

Common problems are lintels failing, posts disintergrating, and door mechanism mounting panels cracking.

Page 27

System L Battery Garage Detail

System L battery garage (for Leofric) started life as a Banbury Garage. When Banbury split into

Compton and Leofric, Compton dropped Battery Garages but Leofric continued with the product. That is why we can still supply parts, fifty or so years later. The main difference between System L and System E is that the System L is built from the rear corners forward whereas System E relies on posts sunk into the concrete base and then built backwards.

System L battery garage is simple. However the original lintel and front gutter design used a metal section, largely hand made. Today we would replace the fronts with System X components.

Before

After

Page 28

System M-8G Battery Garage Detail

Recently the lady using this System M-8G garage shut the door (perhaps too vigorously) whereupon the lintel on her garage, similar to the one on the right, crashed to the ground just missing her. Obviously this is dangerous to the person shutting the door or to children using the garage front for soccer practice or similar activity.

Page 29

These System ME8/9 battery garages are current Marley-designed Leofric built Models and seldom need refurbishment for deterioration but often require repair following vehicle collisions and falling trees or base disruption due to adjacent tree growth. All parts are available, however System LX components will fit to these units to extend building life and enhance apprearance.

System M-H Battery Garage Detail

Page 30

System M-Q Battery Garage Detail

Page 31

System FMTF Battery Garage Detail

Page 32

System FMTR Battery Garage Detail

Page 33

System P Battery Garage Detail

Page 34

System TAR Battery Garage Detail

Note also the gap between panels which shows evidence of a tongue and grooved joint although not as pronounced as a Marley joint. Can be upgraded to System X.

Page 35

System TPP Battery Garage Detail

System V Battery Garage Detail

Page 36

System WMR Battery Garage Detail

System WPF Battery Garage Detail

Page 37

System WNR Battery Garage Detail

System YPP Battery Garage Detail

Page 38

Page 39

1 .

Front Page

9 .

14.

22.

The Index of Existing Systems Garages, System B

37.

38.

39.

40.

Index

Page 40